Metallic Mirrors

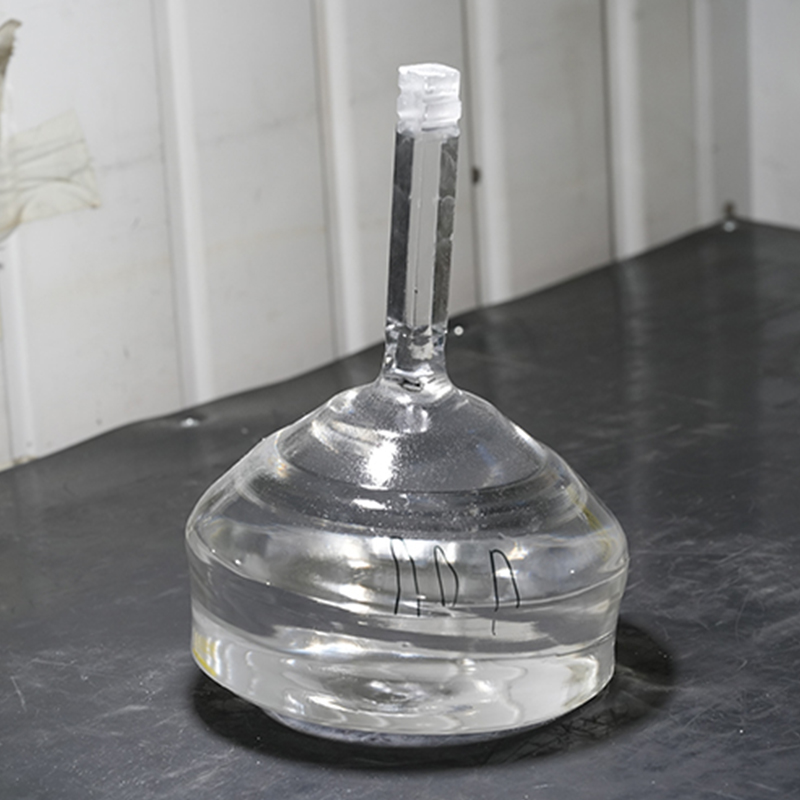

Product introduction:

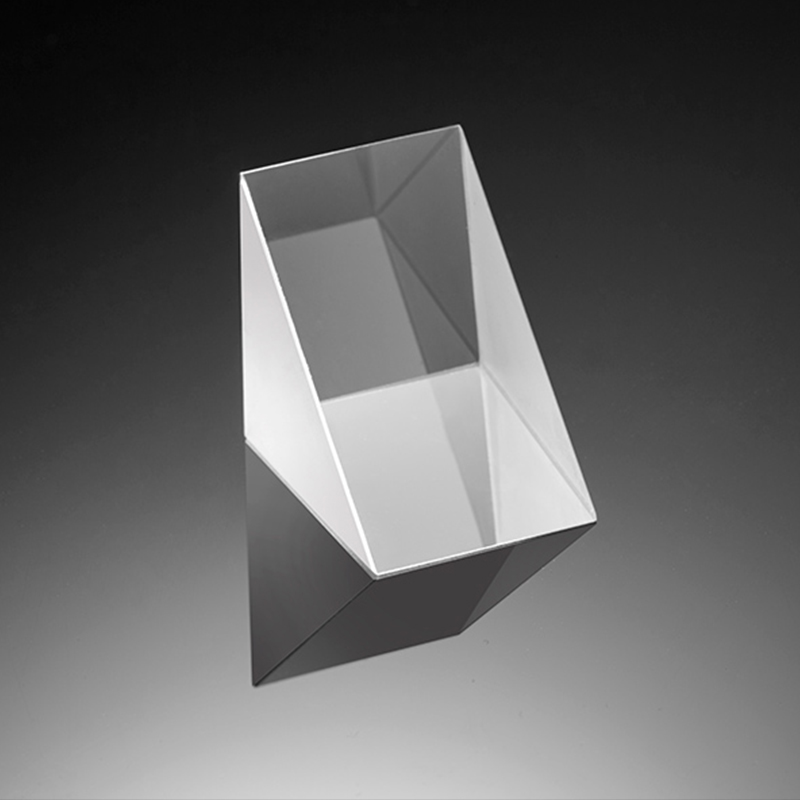

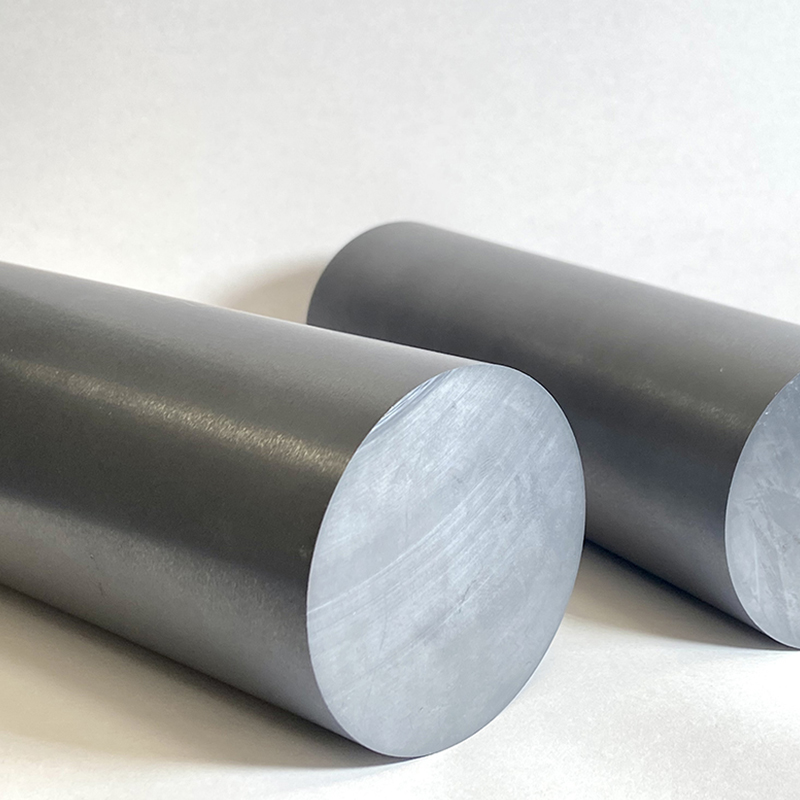

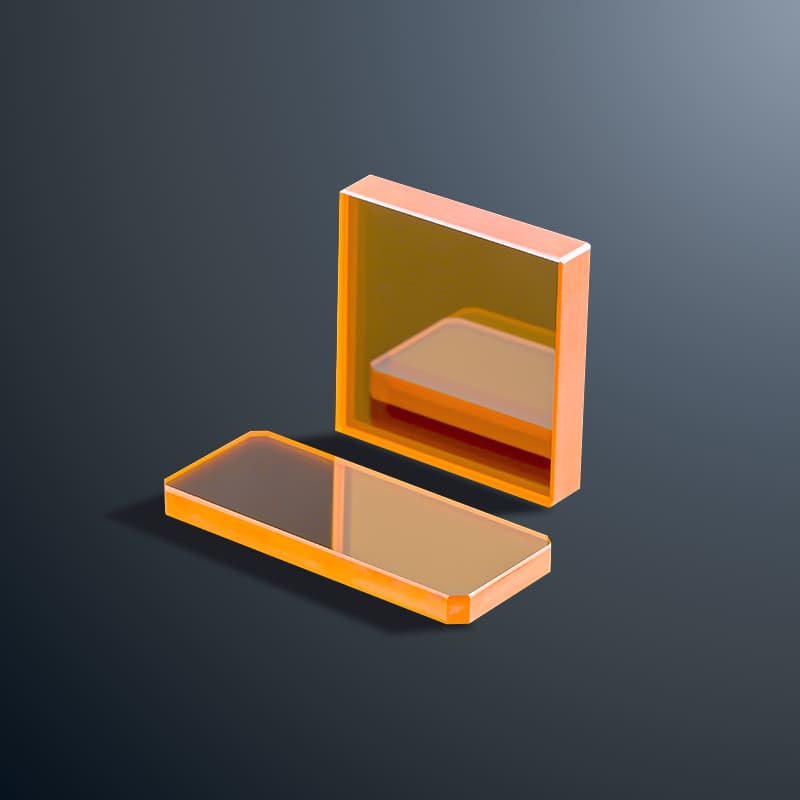

Metallic reflective films include protective aluminum, reinforced aluminum, protective gold and protective silver. Protective and enhanced aluminum films are typically used for visible applications. Protective gold films provide high reflectivity for infrared or near-infrared wavelengths. Protective silver films offer the highest reflectivity between 500-800nm, but are best suited as rear surface mirrors due to their sensitivity to discoloration.

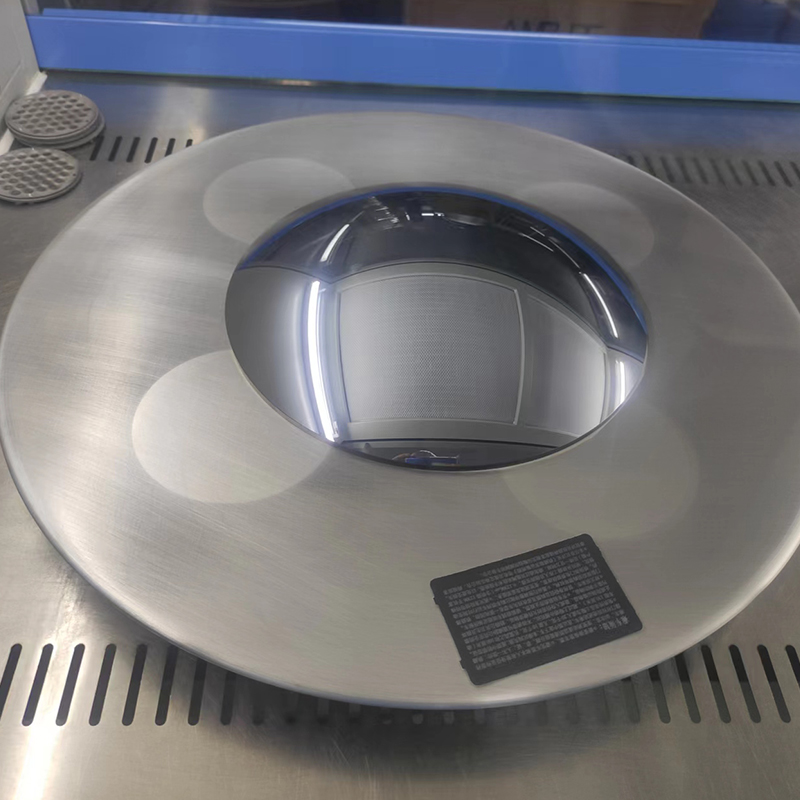

Our company offers a variety of metal film coating services, so you can choose the right film system for your application.

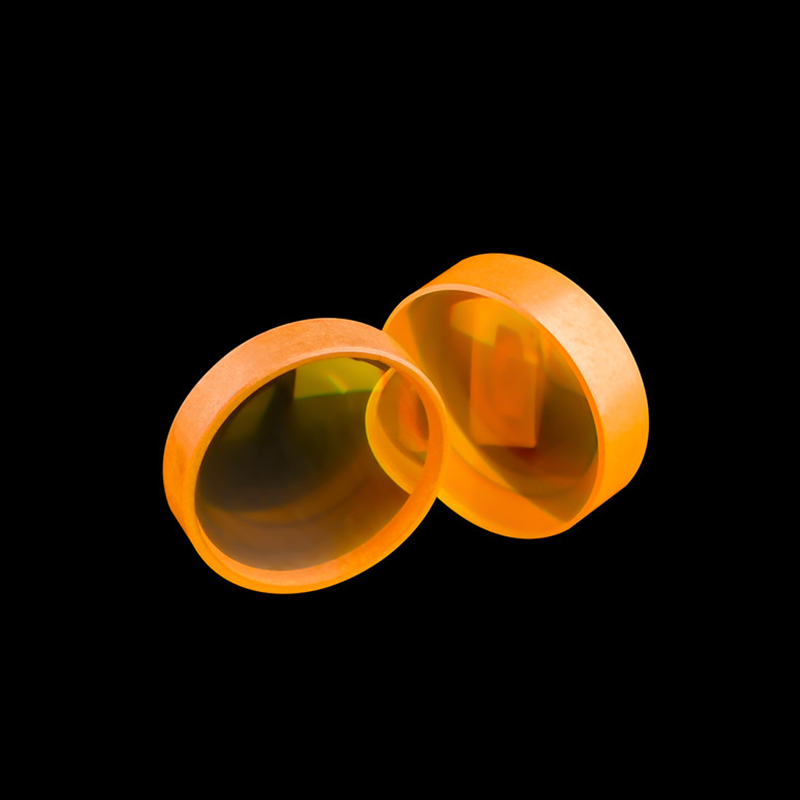

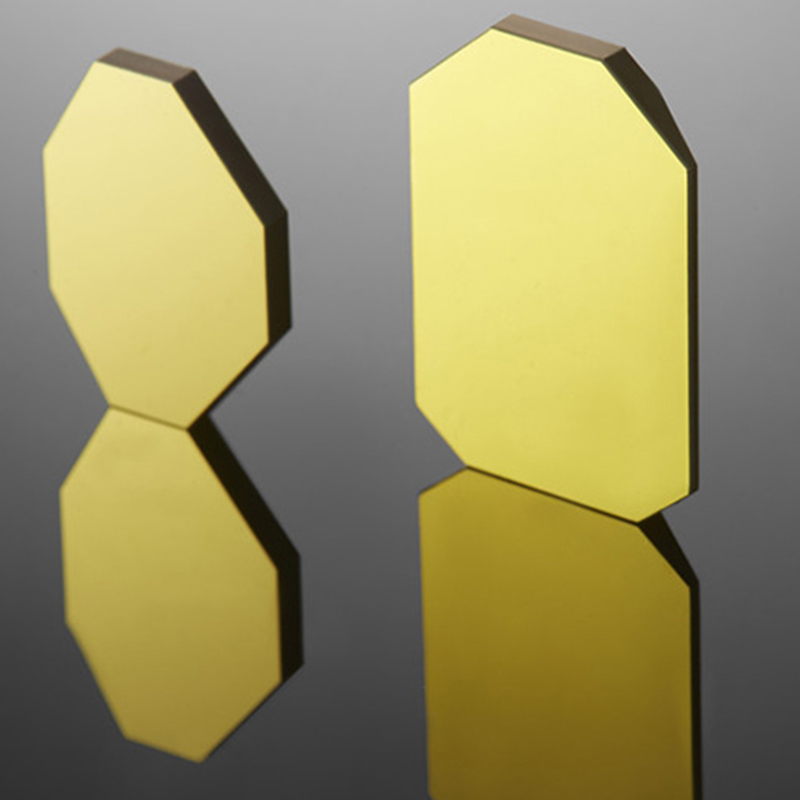

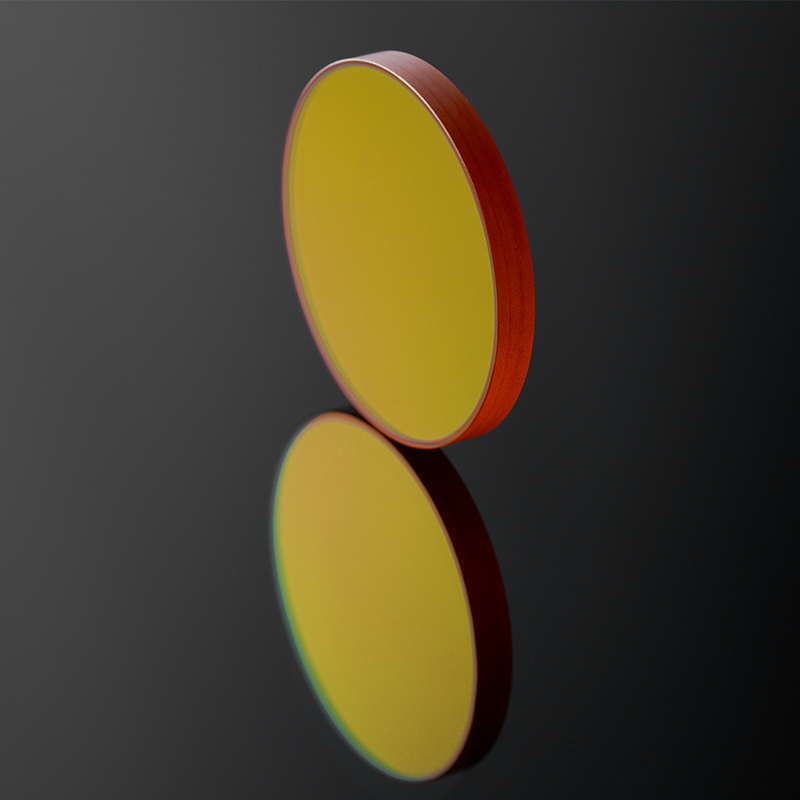

Protective gold films are widely used in the near-infrared and infrared wavelengths where high reflectivity is required. Since these mirrors need to be further assembled and the film needs to be durable, we added a layer of silicon monoxide on top of the gold film. The performance of the gold film remains unchanged, while its durability is greatly improved.

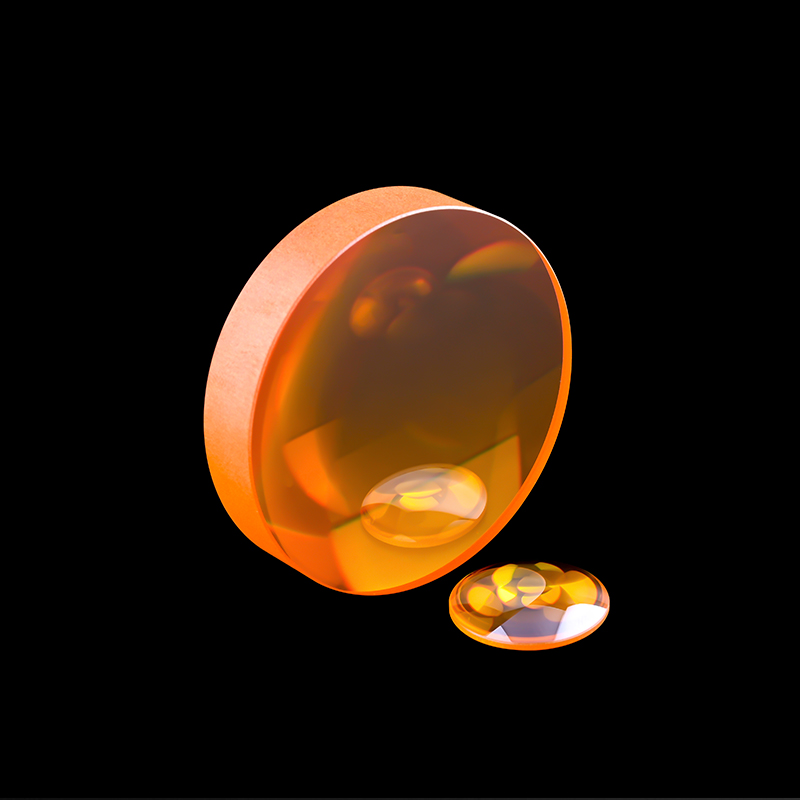

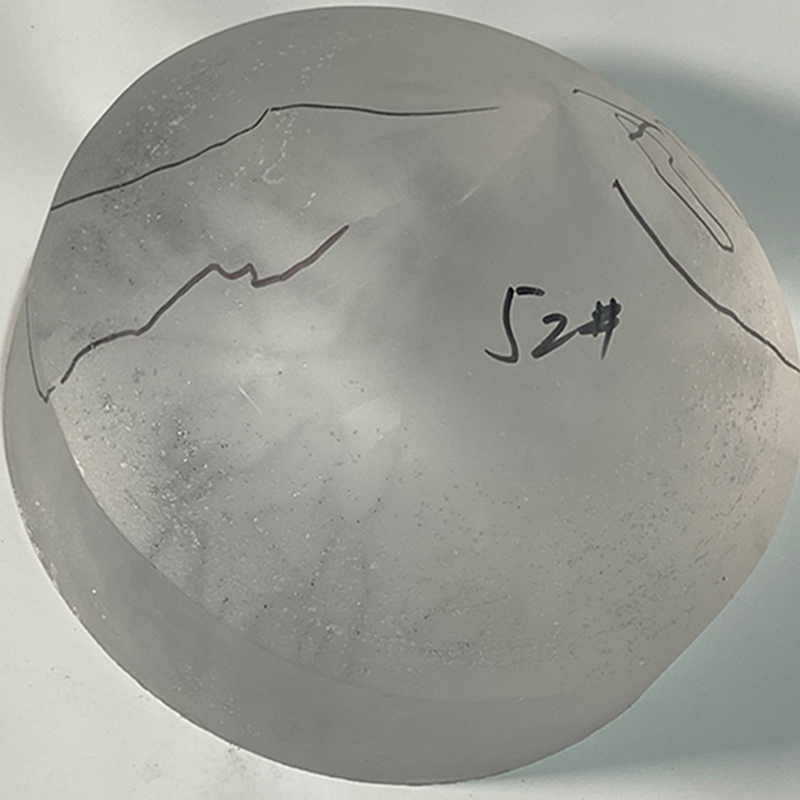

Protective silver films have excellent reflectivity in the visible and infrared regions, making them the best choice for broadband spectral applications. Silver film has >98% reflectivity at 500-800nm, and the protective film reduces the tendency of silver to be contaminated, making it ideal for low humidity environments.

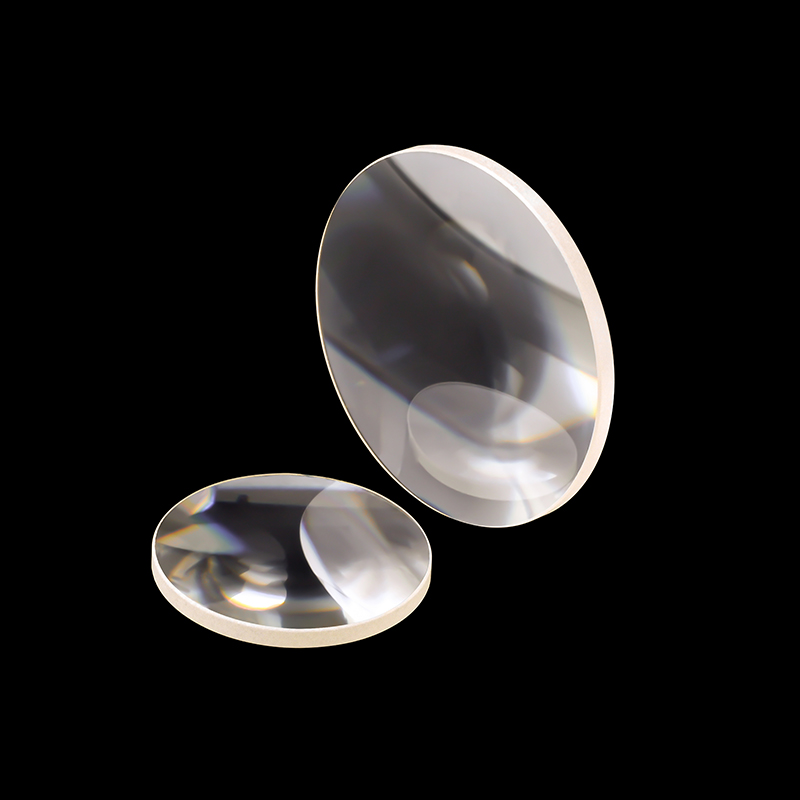

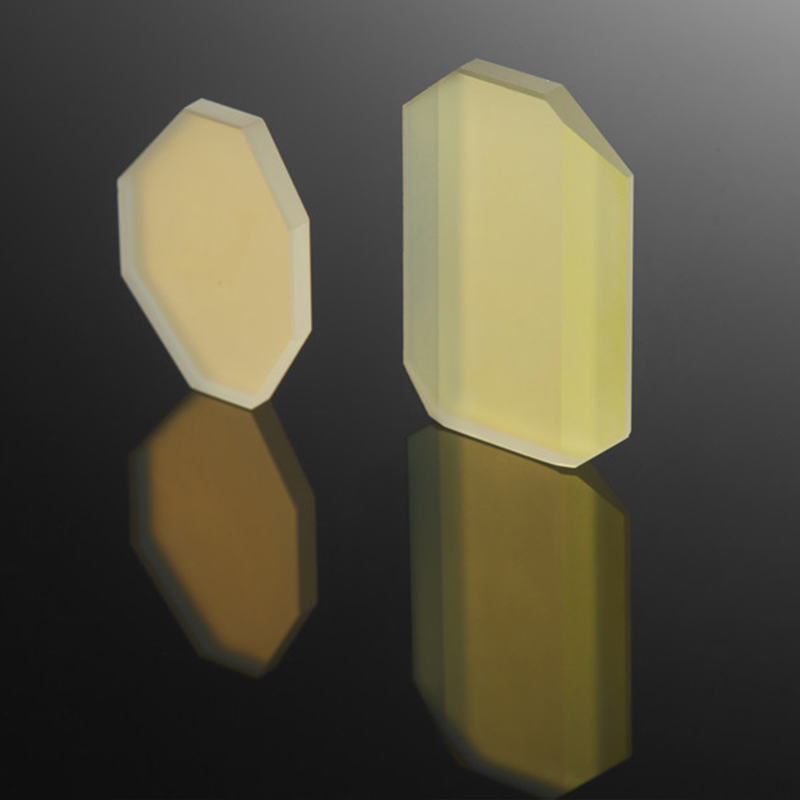

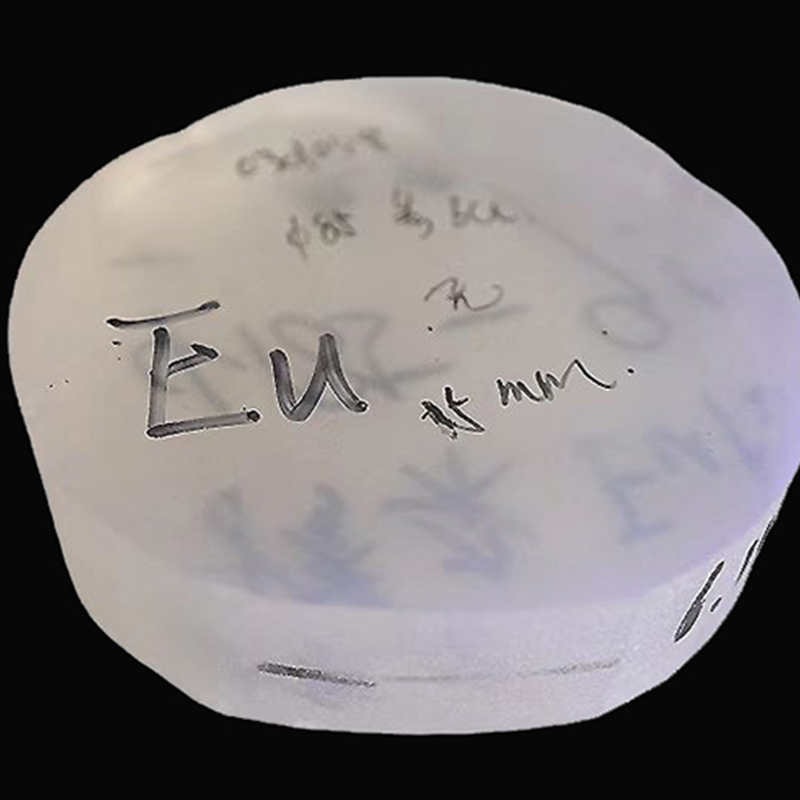

Protective aluminum films are applied to visible and near-infrared light. Half of the wavelength of carbon monoxide (SiO) is used as a coat to protect the delicate aluminum. This method provides a wear-resistant surface while maintaining the properties of aluminum.

The materials commonly used for metal reflective film are aluminum (Al), silver (Ag), gold (Au), etc. Aluminum film is the only material with high reflectivity from ultraviolet region to infrared region, while the surface of aluminum film can generate a thin layer of aluminum oxide (AlOg) film in the atmosphere, which can play a role in protecting the film, so the film is relatively strong and stable. Silver films have high reflectivity in both the visible and infrared regions, and introduce minimal polarization effects when used at an angle. However, the silver film used as the front surface mirror coating is severely limited by the following two reasons: it is poorly adhered to the glass substrate; susceptible to the effects of sulfides and loss of luster. So usually only for short-term role of the occasion or as a rear surface mirror coating. Gold film in the infrared region of the reflectivity is very high, its strength and stability than the silver film is good, so it is commonly used as infrared reflector.