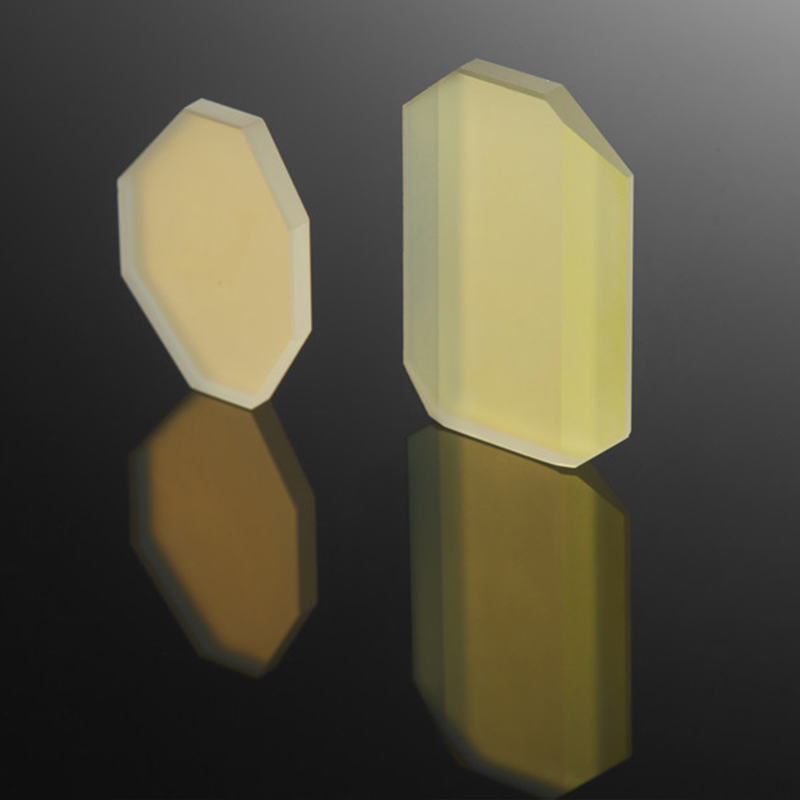

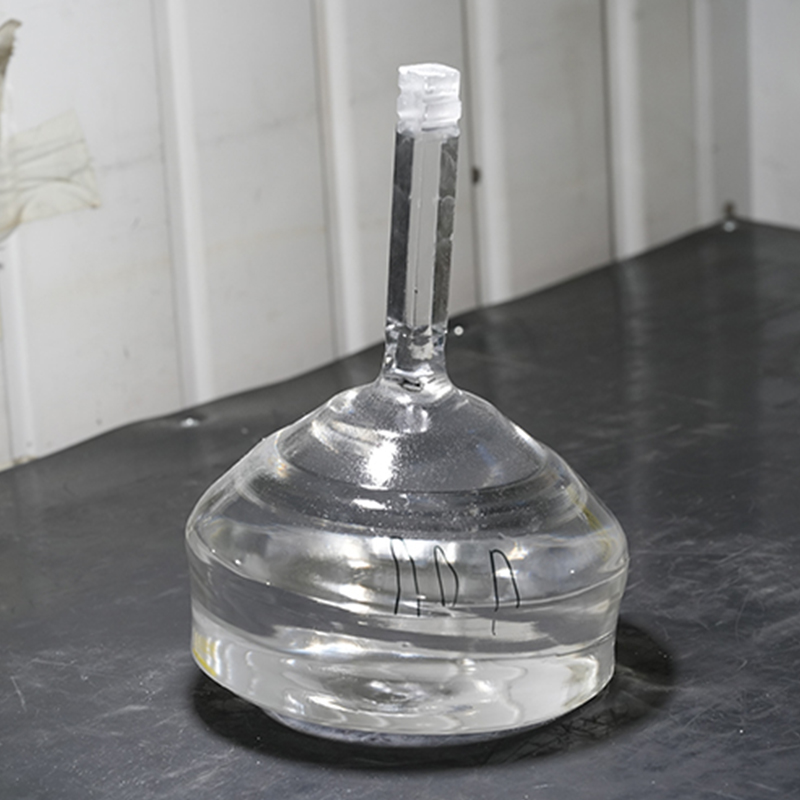

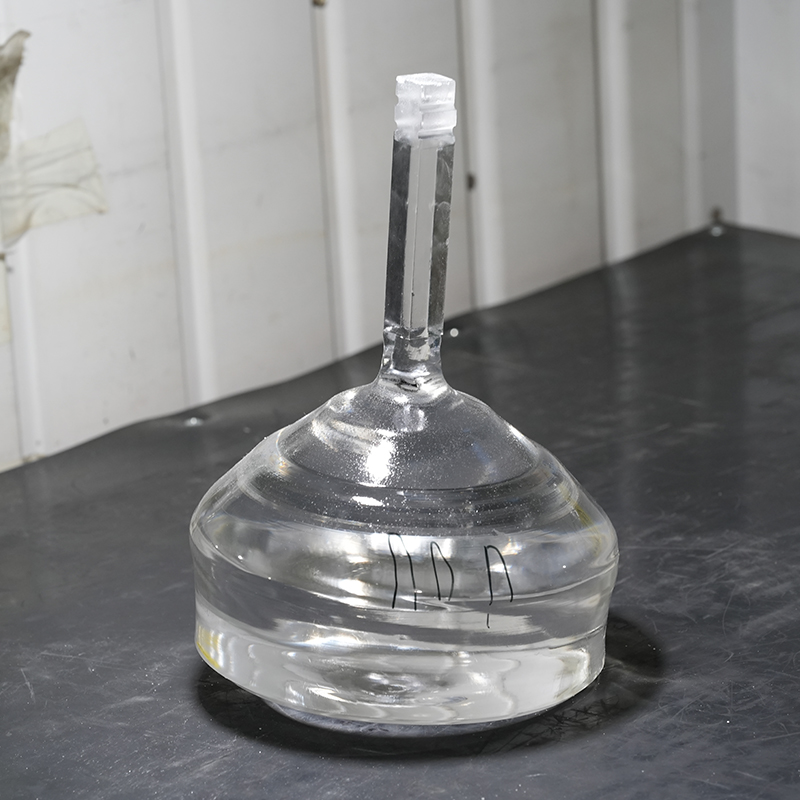

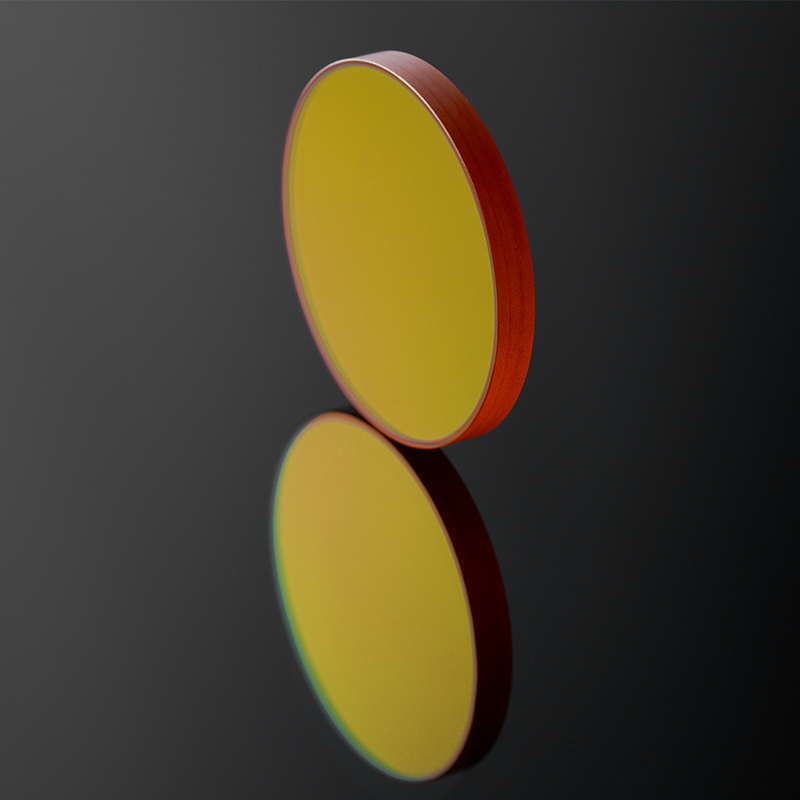

Germanium(Ge) Double-Concave Lenses

Product Introduction:

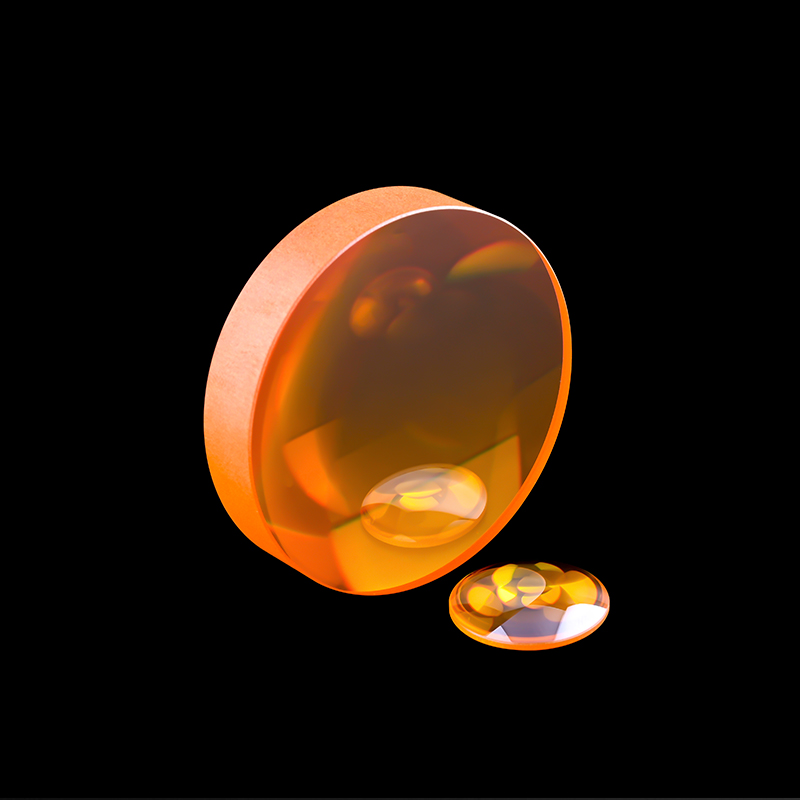

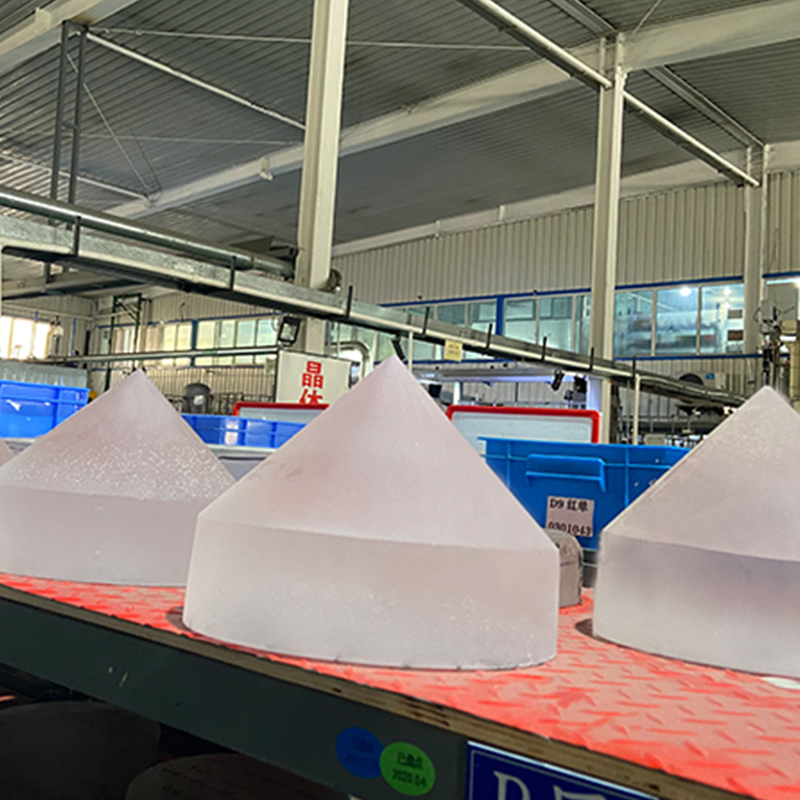

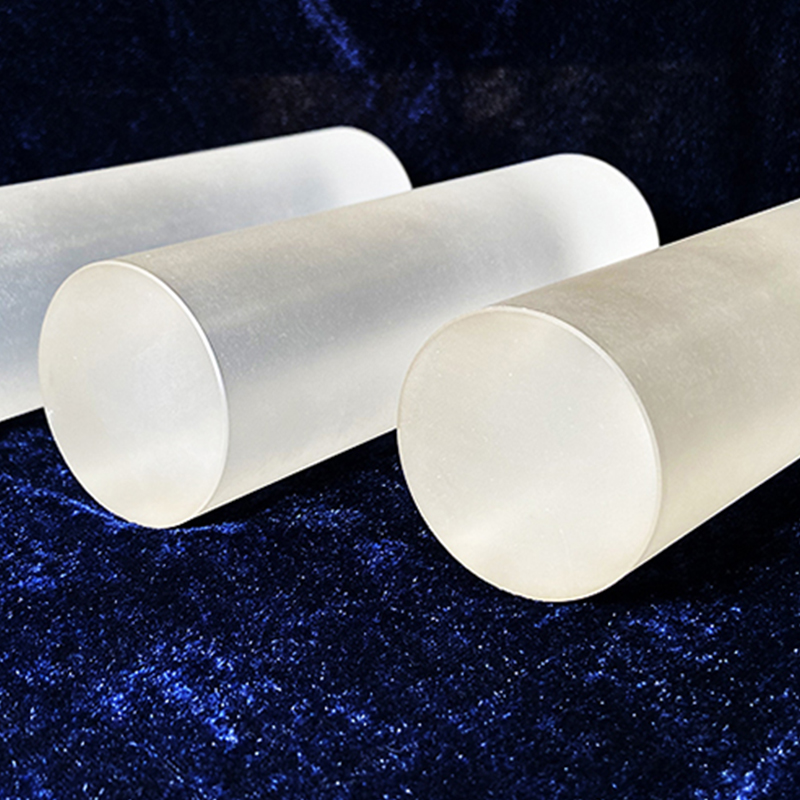

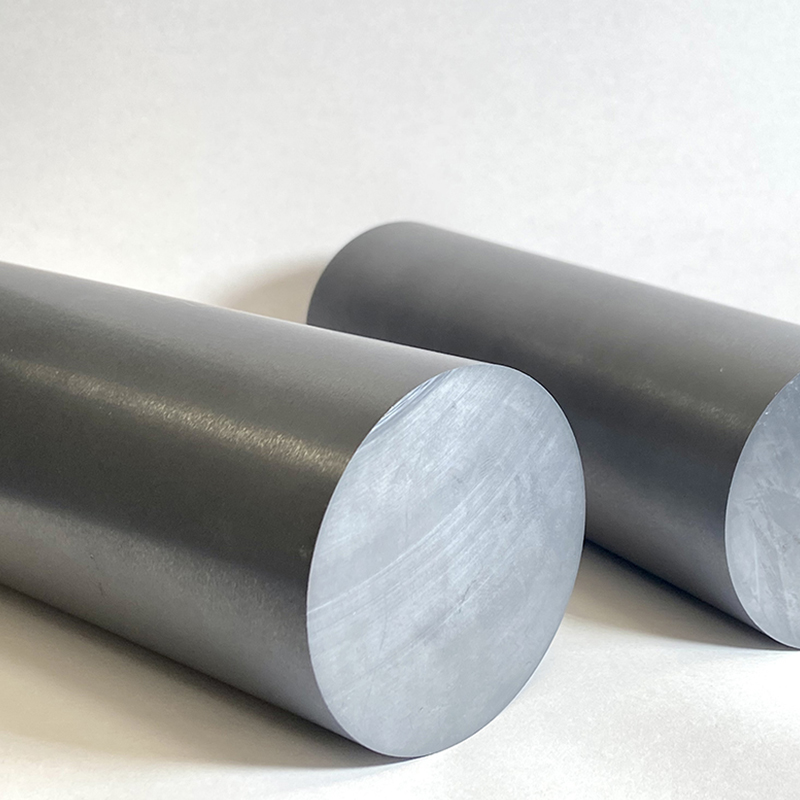

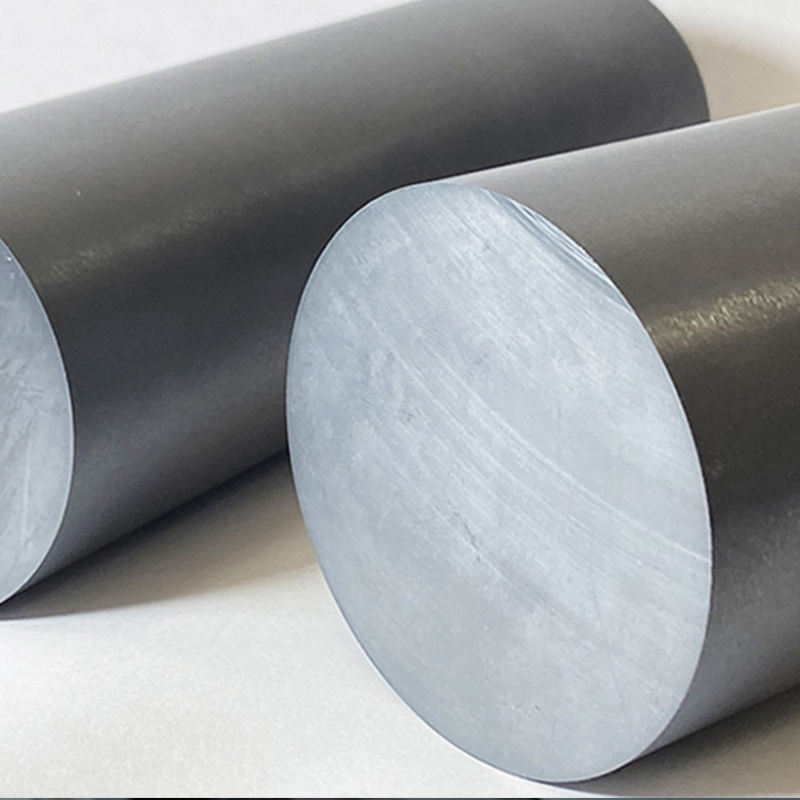

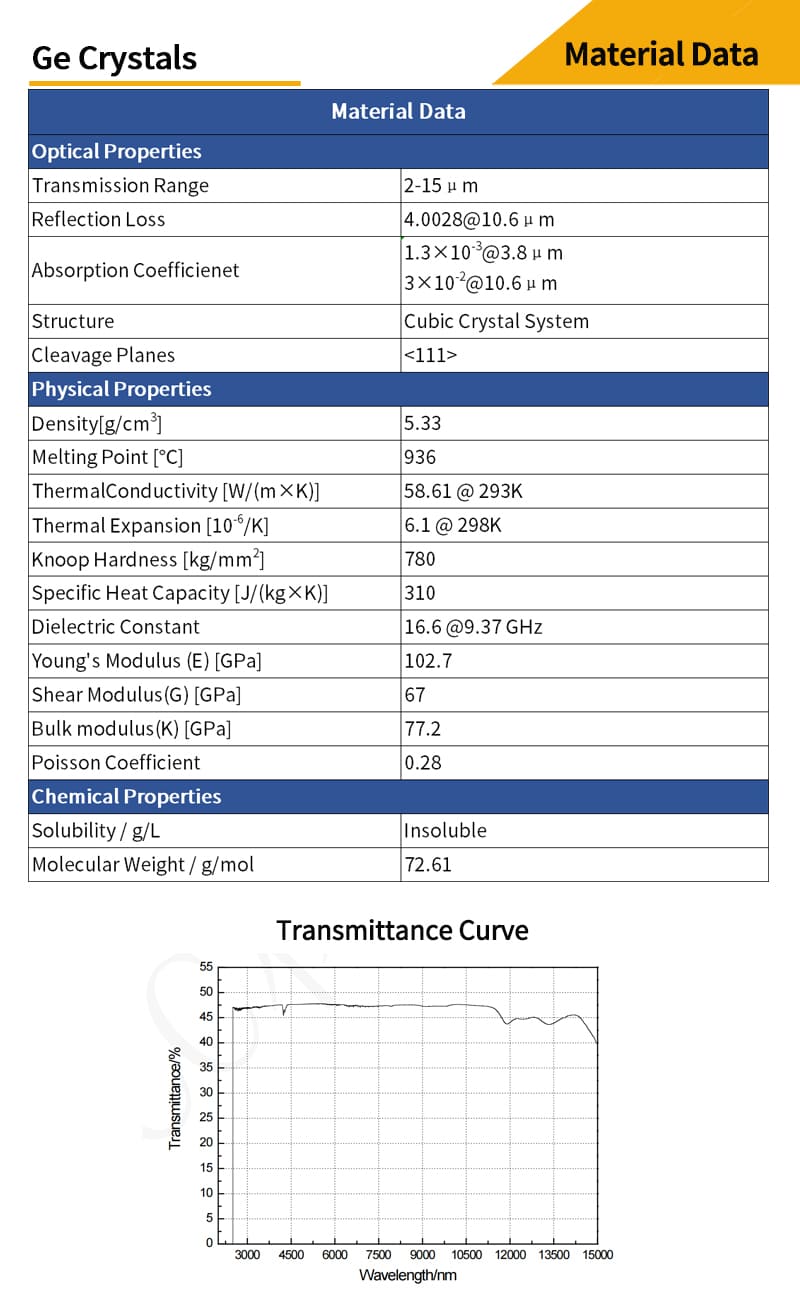

Germanium (Ge) single crystal is a chemically inert material with a transmission spectral range of 2-12 μm. It is a very commonly used infrared optical material with high hardness, good thermal conductivity, and insoluble in water. Widely used in infrared imaging systems and infrared spectrometer systems. Germanium single crystal has good mechanical properties and thermal conductivity, and the absorption at 10.6μm is very small. It is an ideal material for CO2 laser lenses, windows and output coupling mirrors. Germanium single crystals are also used as substrate materials for various infrared filters.

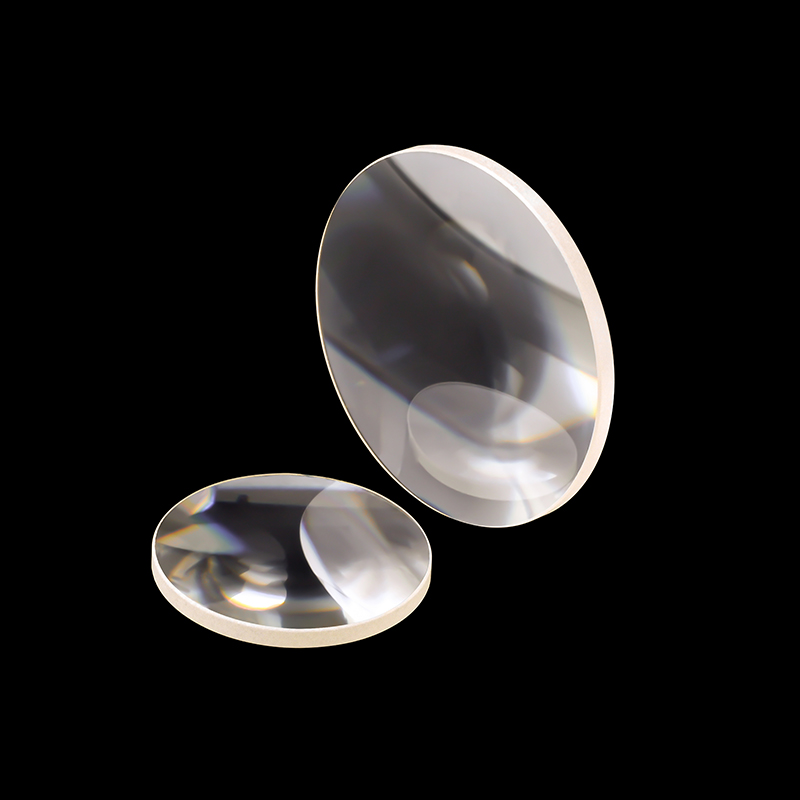

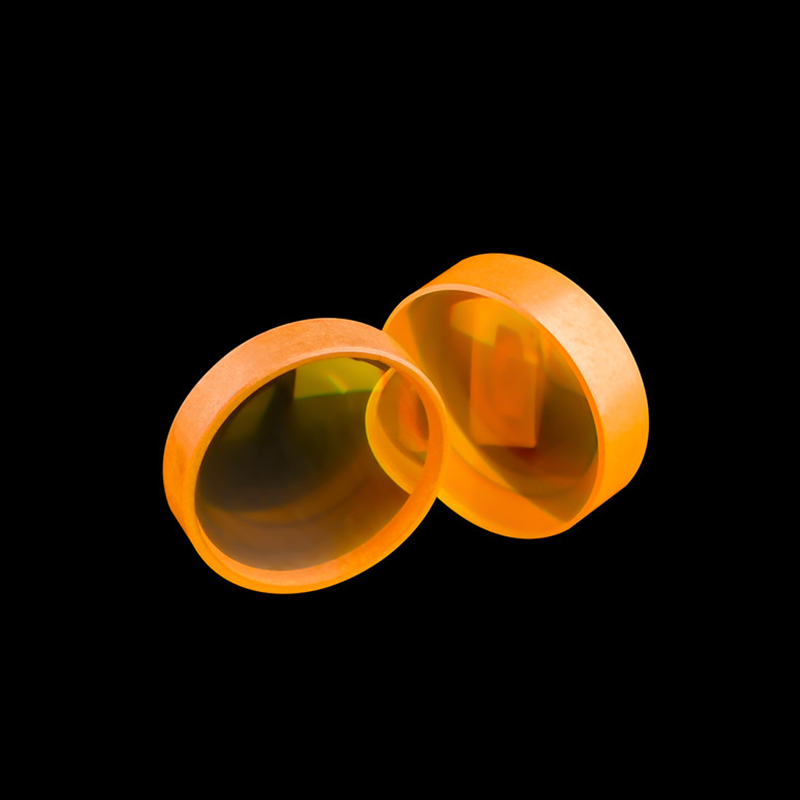

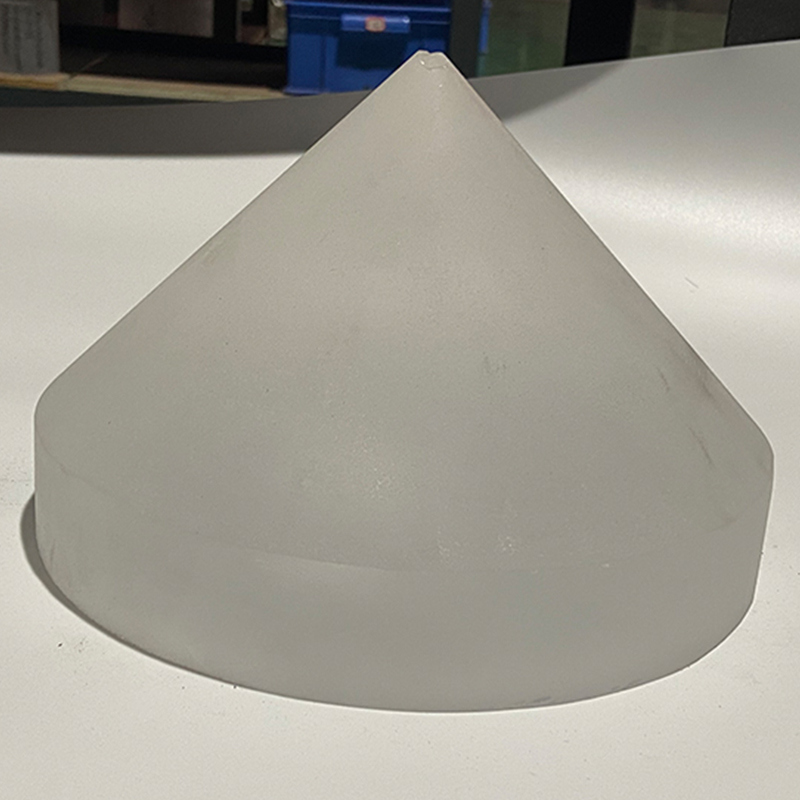

The biconcave lens is similar to a plano-concave lens in that the focal length is negative, but the light incident in parallel diverges outward.

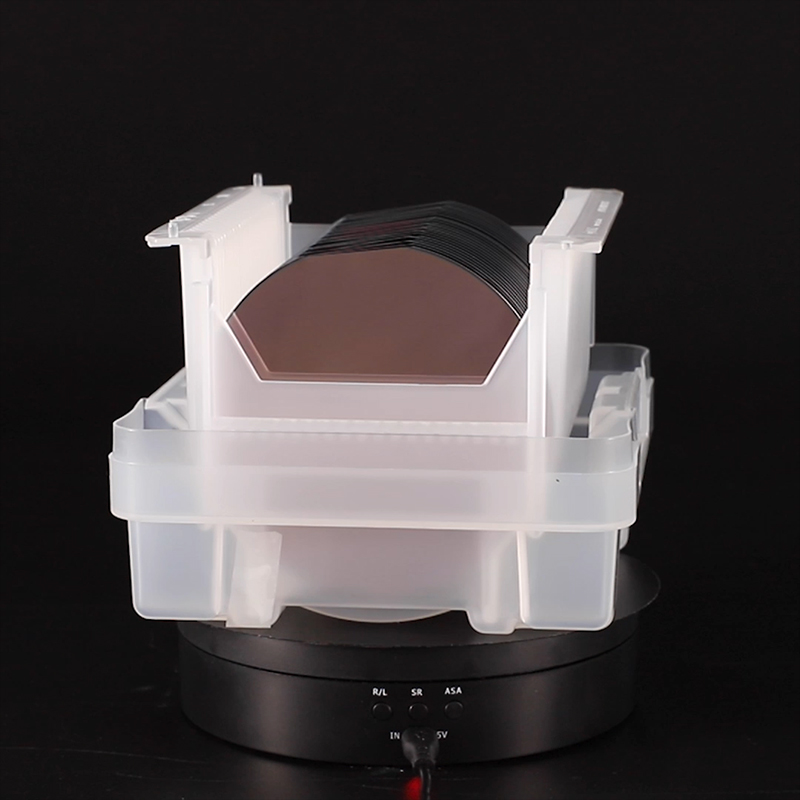

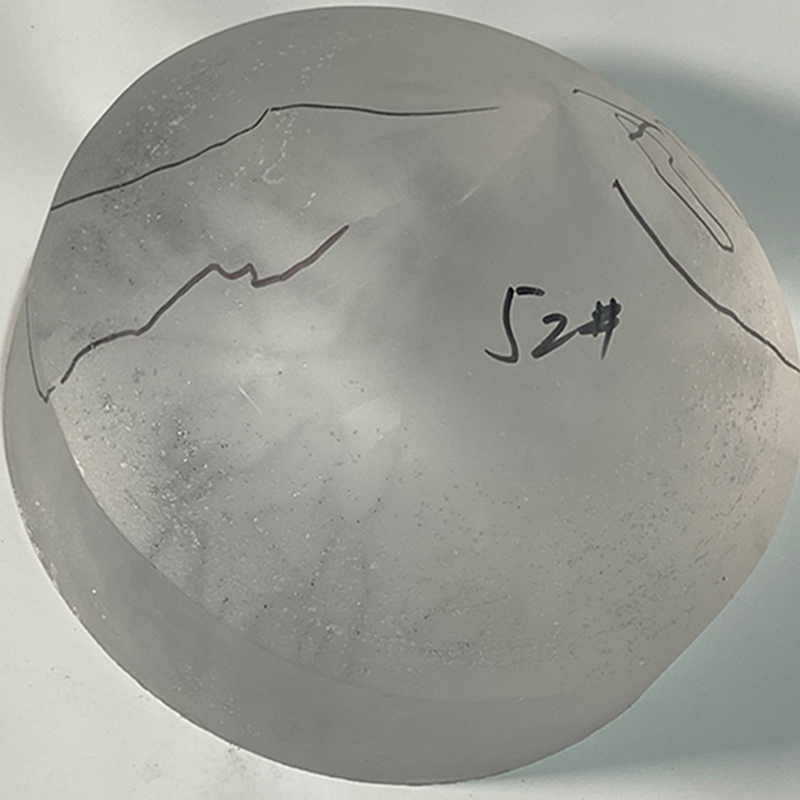

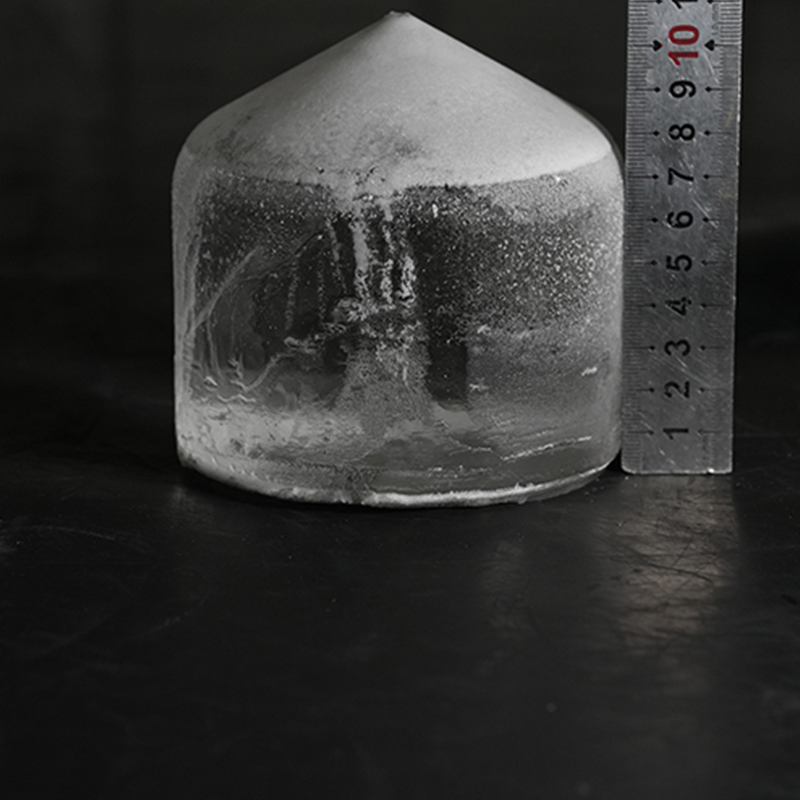

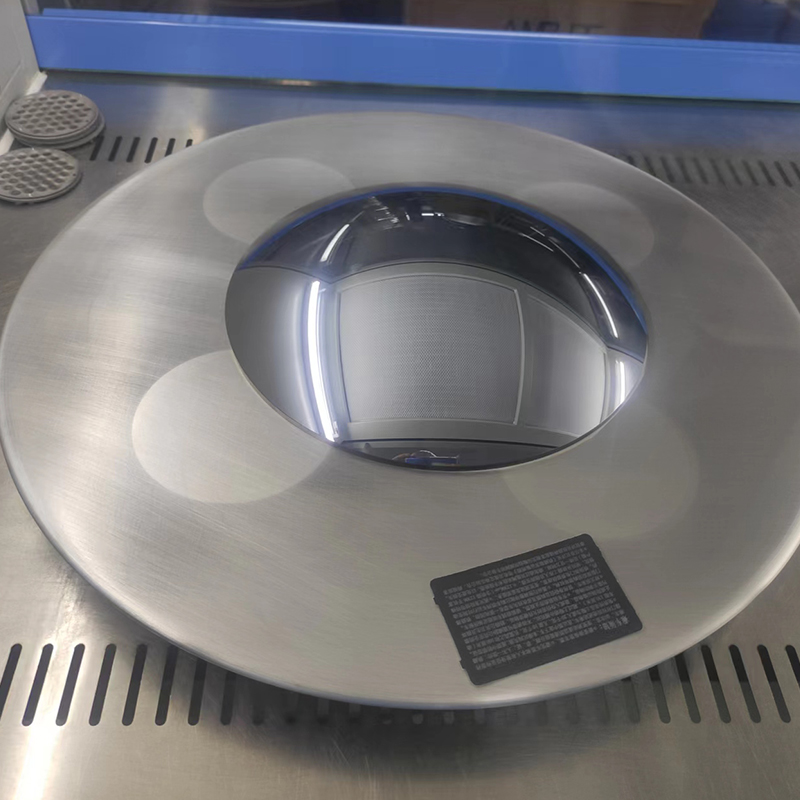

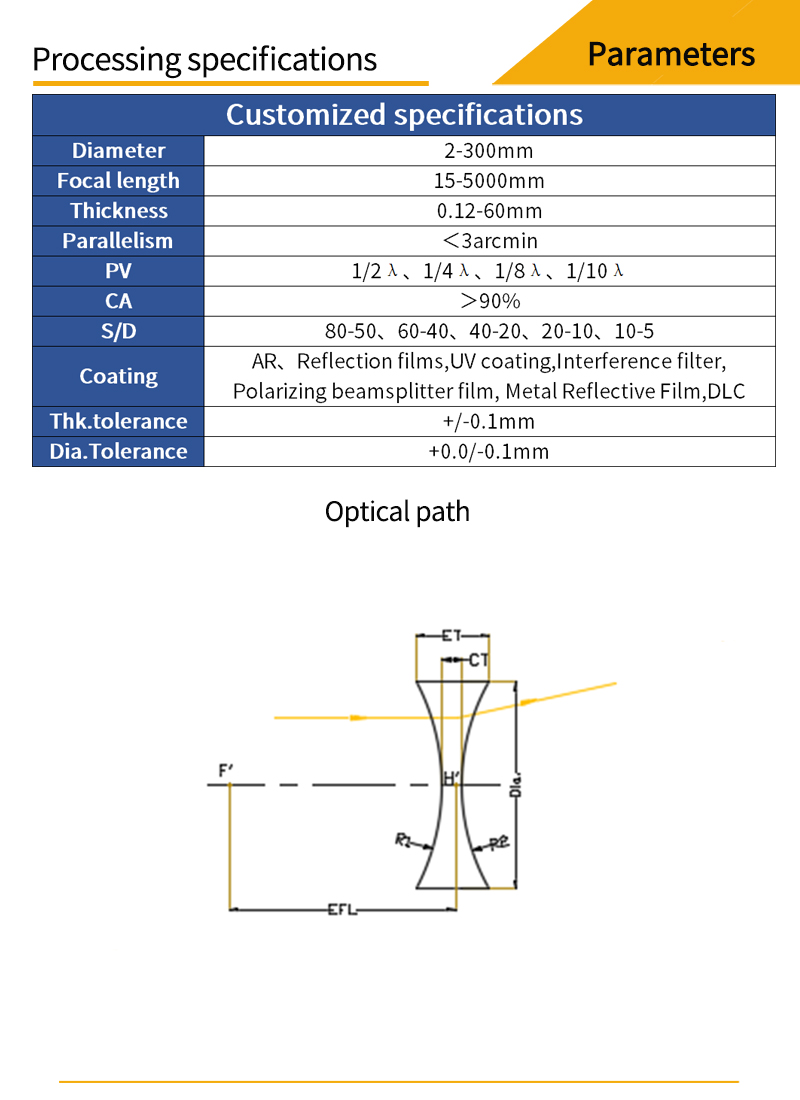

Our Company can provide Germanium Double-Concave Lenses with diameters from 2-300mm and thicknesses from 0.12-60mm (accuracy up to 20-10, 1/10L@633nm), with 4 major processes: gel disc polishing, high speed polishing, ring polishing and CNC polishing, with ZYGO, AFM, reflection and transmission eccentric meters, 15 second goniometer, UV gel centering system, non-contact Laser. Thickness gauge, 2D imager and sphere diameter gauge to ensure the accuracy of data.

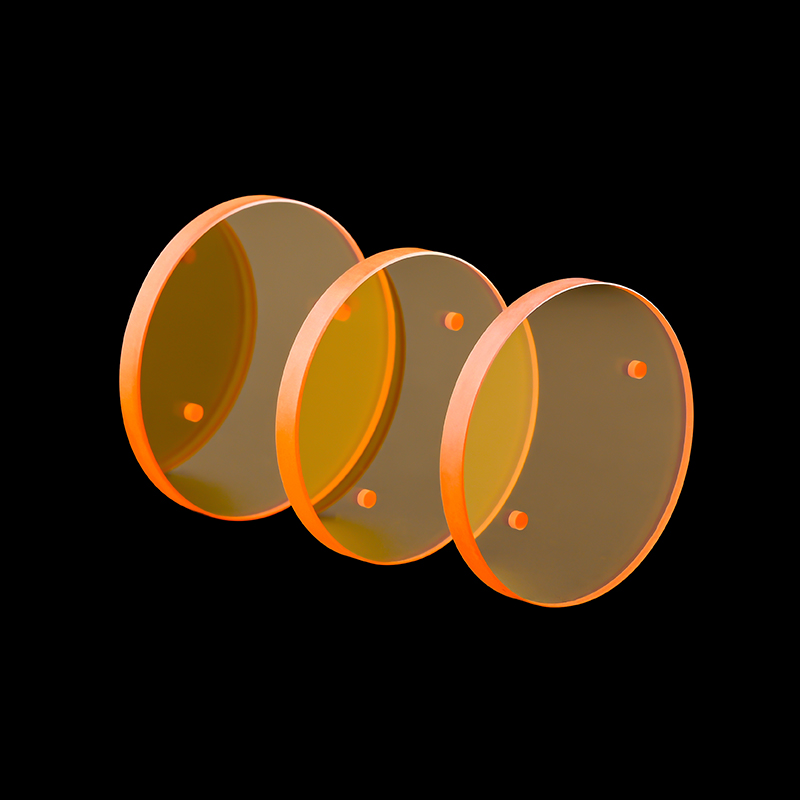

Coating selection:

MgF2,UV-AR,UV-VIS ,VIS-EXT, VIS-NIR, NIR I, NIR II, Telecom-NIR,SWIR ,SWIR ,YAG-BBAR.

Germanium is widely used because of its high refractive index, large transmission distance range and robust mechanical properties. Optical grade germanium crystal has a wide infrared transmission band (available in both 3~5μm and 8~12μm bands) and is a good material for making infrared optical lenses, mostly used in thermal imaging cameras and infrared lasers. However, germanium is subject to thermal fugacity, i.e., the transmittance decreases as the temperature increases.

Our company offer germanium biconcave lenses in various sizes and focal lengths.

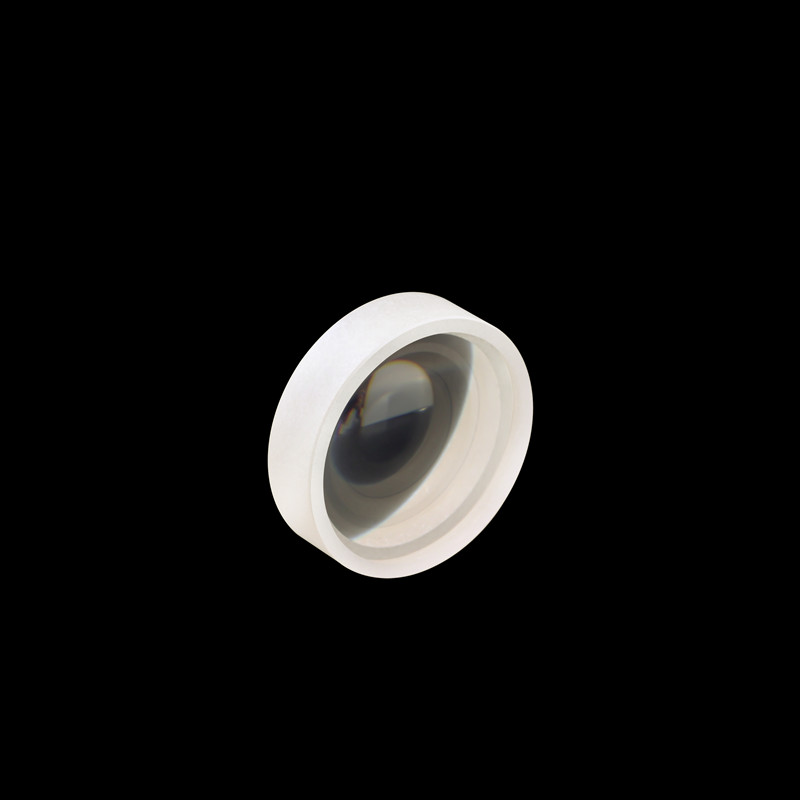

Biconcave lenses have a negative focal length and consist of two concave surfaces of equal curvature, which can disperse a parallel incident beam outward and are commonly used for beam spreading, collimation, projection and focal length expansion of optical systems. Biconcave lenses disperse a collimated beam to an imaginary focal point and are commonly used in Galilean beam expanders.

The important parameters of biconcave lenses are: size, focal length, design wavelength, finish, face accuracy, eccentricity, substrate material and other attributes. Suitable parameters of biconcave lenses can be selected according to specific applications.

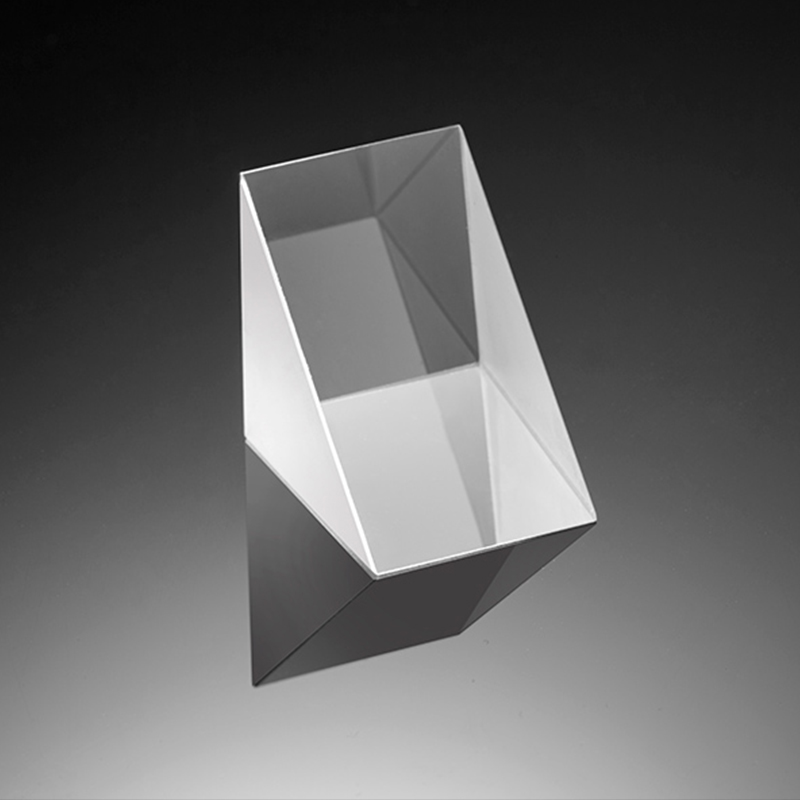

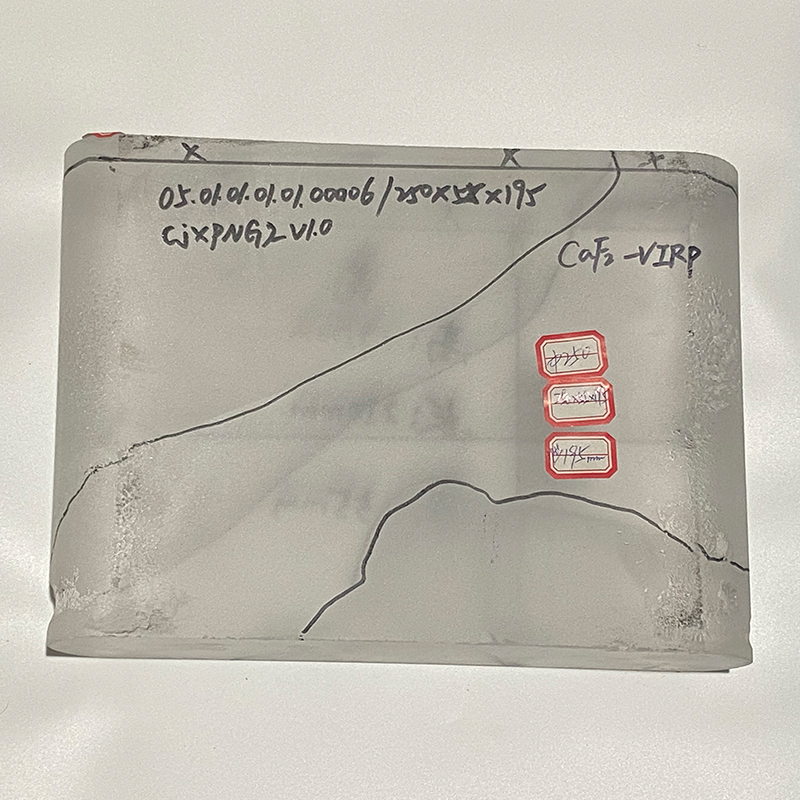

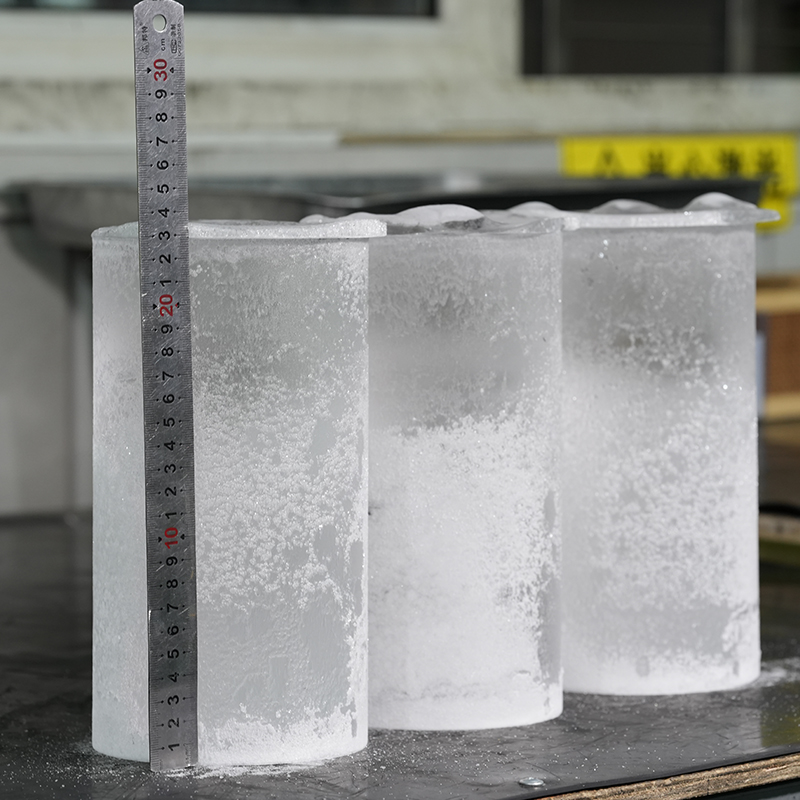

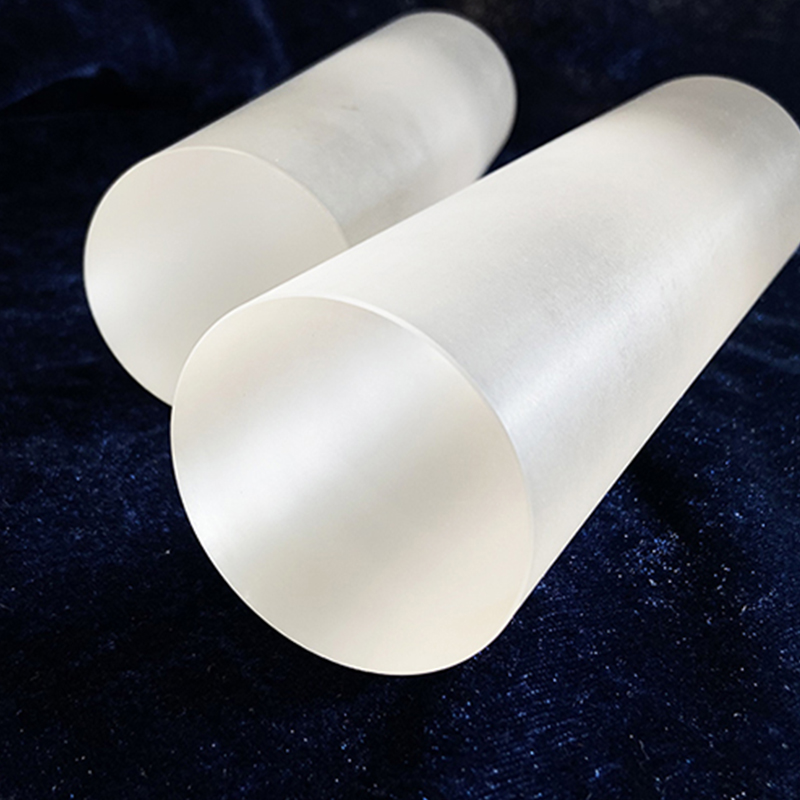

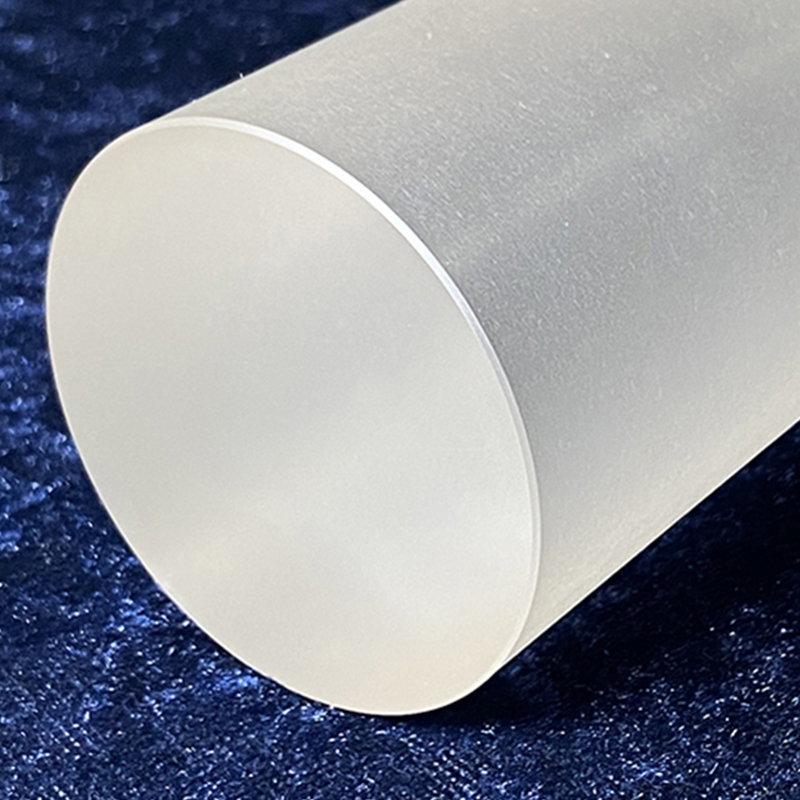

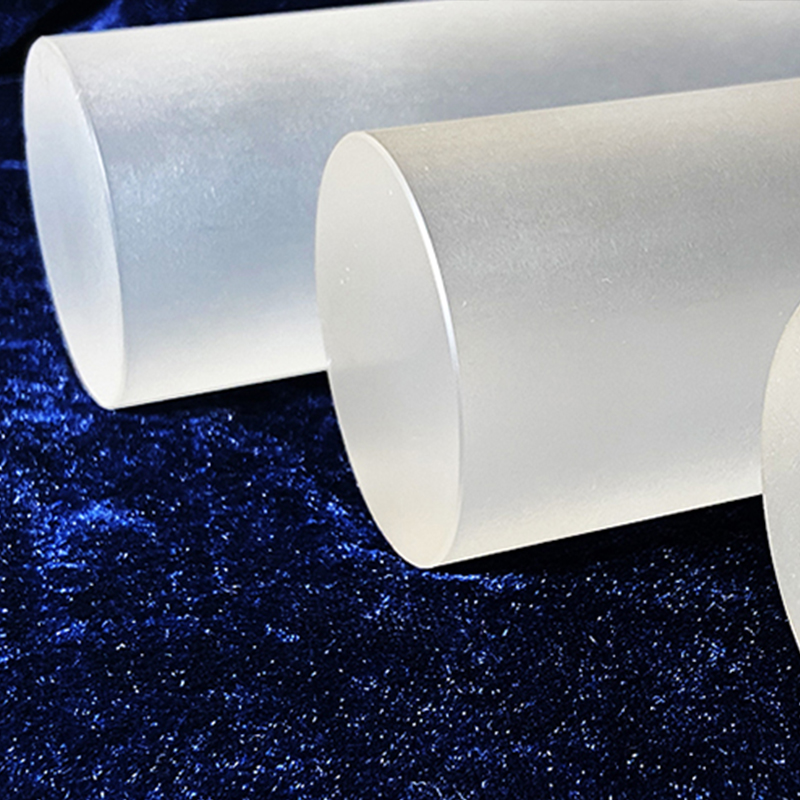

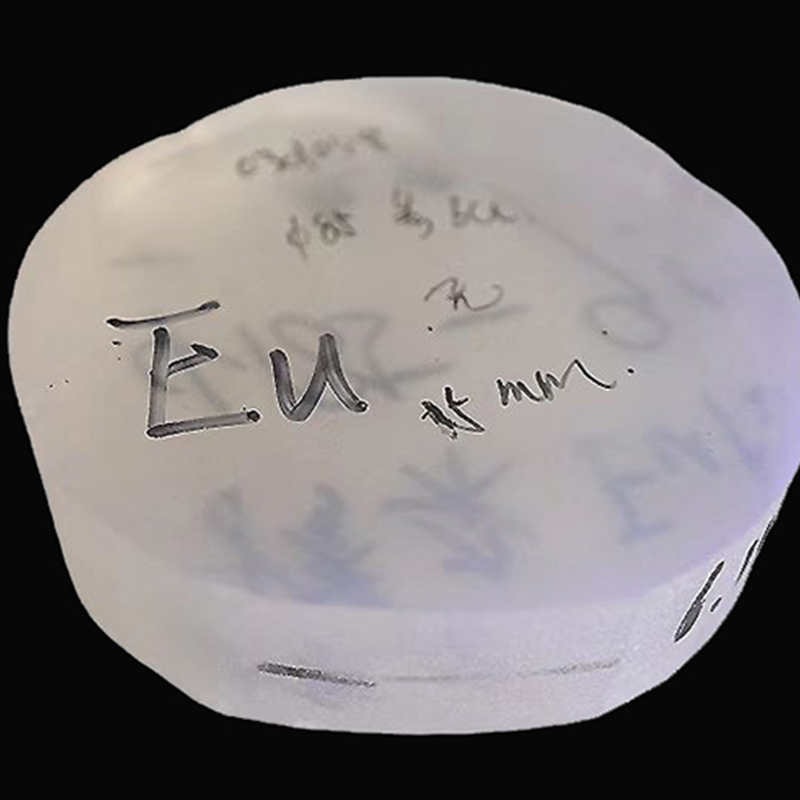

Calcium fluoride (CaF2), colorless cubic crystal, insoluble in water, is one of the few natural crystals that exist in nature, and has important applications in the optical industry because of its good optical properties, such as wide transmission range, high transmittance, low refractive index, and large relative dispersion.

Calcium fluoride(CaF2) crystals are widely used as window, lens, prism, beam splitter and substrate materials from vacuum UV to mid-infrared wavelengths because of their high transmittance and very high laser damage threshold in the deep UV region. High purity calcium fluoride single crystals are good window materials for lasers in the vacuum UV band, and single crystals or hot forged single crystals are window materials for carbon monoxide and chemical lasers.The good optical properties of calcium fluoride crystals in the vacuum band are unmatched by other materials.Calcium fluoride single crystal materials for this band also have the advantages of radiation resistance, high ozone resistance, fluorine corrosion resistance, and low cost.

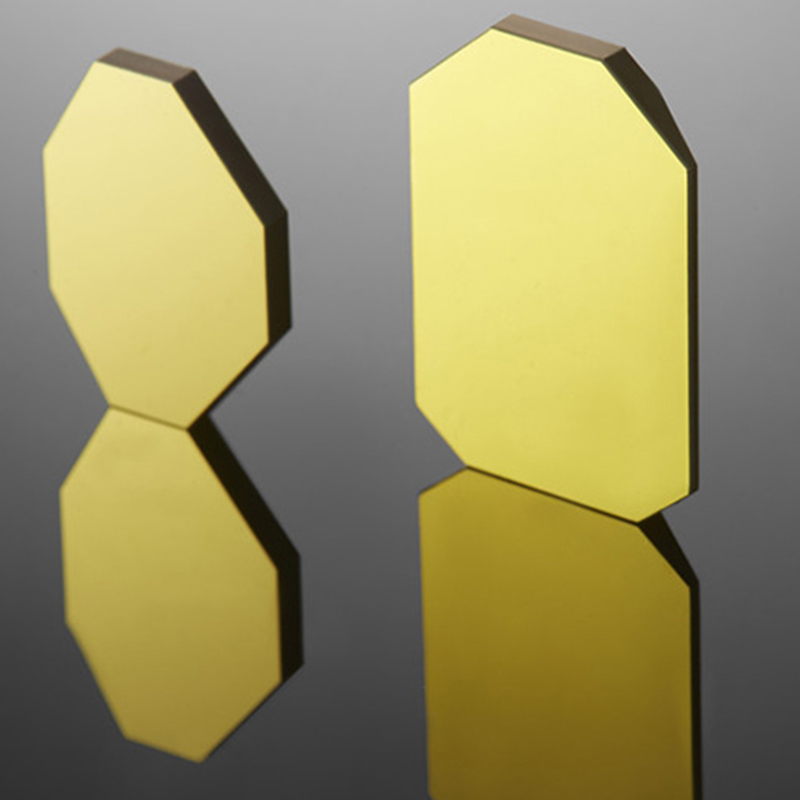

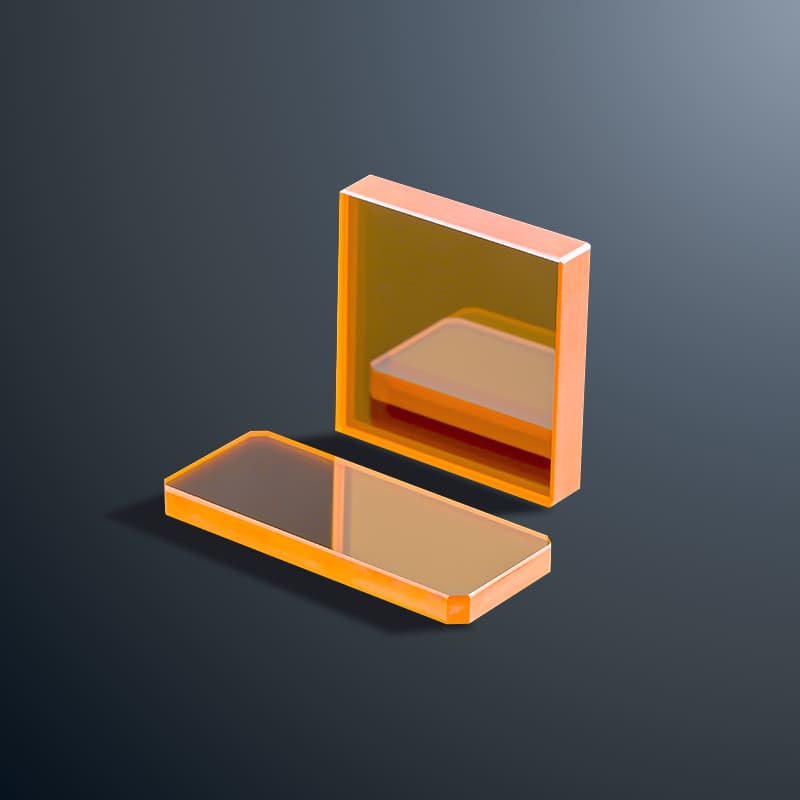

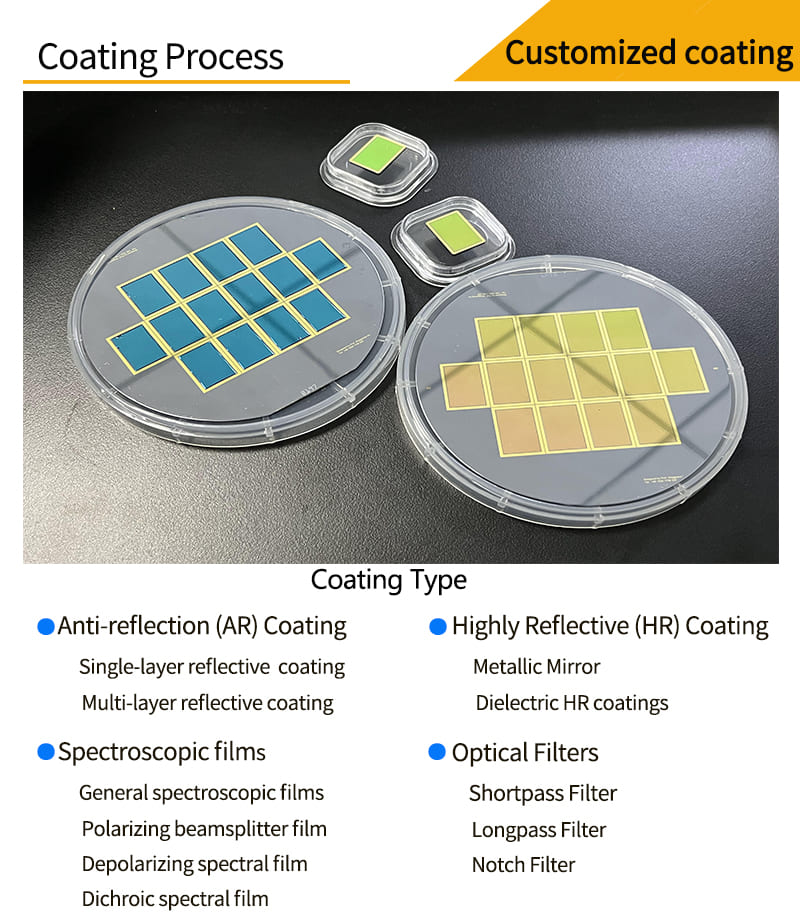

Coating refers to coating a transparent electrolyte film or metal film on the surface of the substrate material by physical or chemical methods. The purpose is to change the reflection and transmission characteristics of the material surface to reduce or increase the reflection, beam splitting, color separation, light filtering, polarization and other requirements.We can provide various optical coatings such as anti-reflective films, high-reflective films, spectral films, and metallic films. Broadband anti-reflective films are available for UV, visible, NIR and mid-infrared wavelengths.